The 9 bolt gearsets will run fine with standard 80w90 hypoid gear oil. If you are running a posi unit you will need 90w posi gear oil. Friction modifier is optional if you experience clutch chatter. For heavy duty use (towing/race or short ratio gearing >3.45) I recommend 85/140 gear oil for it's better lubrication properties under extra load and heat. This is the case in both posi and non posi setups.

I often get asked how strong the 9 bolt is. It's a difficult question to answer definitively with the factory rating being only around 220kw (at the axle) The 4 pinion posi carriers are almost indestructible. The only time I've even seen them break is when the cones are bottomed out and the spiders are way out of mesh, or when single wheeling burnouts (worn cones) cause the spiders to bind on the X-shaft. In a properly setup 9 bolt the 28 spline axles will be the first to go. They usually show signs of twisting around the mid 10 second quarter mile mark, although this is highly dependant on shock loading. The 9 bolt axles are made of better material than standard OEM 9" 28 spline axles. If the limit is reached 31 spline conversions are available (email) and take care of the weakest link.

The gearsets vary on strength depending on ratio somewhat. Wheel standing a 1500kg vehicle on slicks running 9.6 down the quarter is yet to break a 2.77 ratio I've been testing. Although this setup is running billet 31 spline axles. This was without a TA cover running stock cap bolts... Not bad for a 7.5" ring, although most are 7.75". This is testament to quality materials.

Some tips for beefing up your 9 bolt:

Make sure contact patterns are correct! Many people fit gears without checking the pattern or think near enough is good enough. This is not the case. Simply taking it to a mechanic doesn't ensure the job will be done right either. Google rear end shops and find reviews and ratings before parting with hard earned dollars and expensive parts. I have had a few emails from people stating that the ''the shop said the gears won't fit my 9 bolt" which is often after the whole rear has been torn down and the car is sitting un-drivable on the hoist. I triple check everything before sending parts. If in doubt about your setup or mechanic email me before getting the job done.

This one is important for all differentials. Make sure all bearings are in good condition and prelaods are set correctly. Sloppy bearing preload allows the crown / and or pinion to vary greatly in relation to each other under load. If you've set up contact patterns before you will know what difference even .002" makes to a pattern. If you've got .010 of slop in your pinion bearings or carrier bearings imagine how terrible the pattern must look under load with all the slop taken up to one side (thrust) and the pinion cocked away from the crown in the housing.

Make sure the posi is shimmed correctly, badly meshing spiders will break. Posi shimmed too tight will stretch the carrier bolts and destroy bearings/backlash/gears.

At higher power levels with good traction and high shock loading (slicks/transbrake or Button clutch manual) consider running a few beads of weld around the tubes where they are pressed into the housing as a precaution to prevent them from rotating.

Carrier cap studs and cover girdle are great for keeping everything rigid and in place. Plus thr extra cooling and oil capacity of alloy cover plates is great for the health of the fluid.

If you want your 9 bolt (or any rear for that matter) check all bearing preloads are correct, MAKE SURE MESH IS CORRECT, and you should not have any unexpected problems.

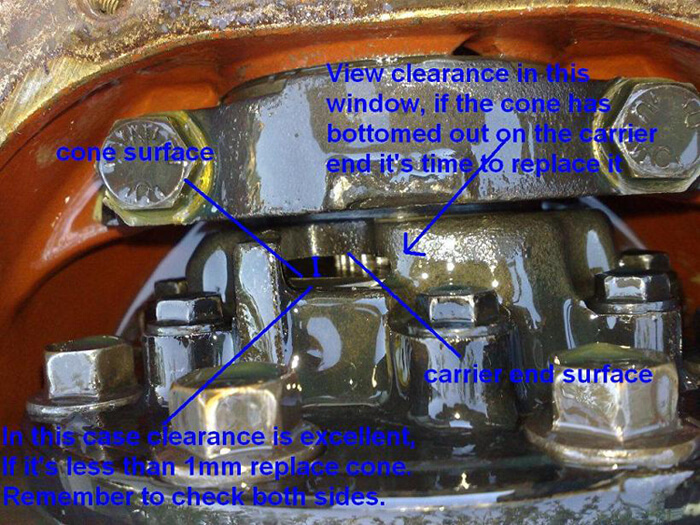

The following image shows a posi carrier that has new posi cones fitted. Over time the posi cones wear deeper into the ends of the carrier, and the clearance gap is reduced. Eventually the cones will bottom out on the ends of the carrier and the carrier will then only function as an open centre. I would not recommend running cones with less than .030" clearance as although the posi will still function it won't be long before the cones bottom out and require replacement. This example shows new cones with plently of clearance. Remember there are two cones (one each end) and they often wear at different rates.

Secure car safely with wheel chocks etc, remove handbrake and place gearbox into NEUTRAL. Raise one rear wheel from the ground . Measure the torque required to rotate the wheel that is off the ground. This is called the breakaway torque, and if less than around 35lb/ft the centre requires attention -- either shimming or cone replacement. If the carrier is not currently installed the breakaway torque can be tested by securely placing an axle in a vice, with the splined end pointing straight up. Sit the posi unit onto the axle in the vice and place a second axle into the posi. Measure the torque required to rotate the second axle.

NOTE: A very quick test can be done without the use of a torque measuring apparatus by hand by attempting to rotate the raised tyre by hand. As a rough guide an average person should have a reasonable amount of difficulty rotating the raised wheel, if able to do it at all.

All enquiries can be directed to: sales@9bolt.com